Daher is focusing on thermoplastics as the material is “promising for the production and assembly of aerostructures” – for which the company has a Tier 1 supplier role to leading airframers such as Airbus, Boeing, Dassault and Gulfstream – said Dominique Bailly, Daher’s research and development director.

Speaking to FINN, Bailly said: “Daher’s emphasis on thermoplastics benefits from two aspects that are unique to the company. The company has a significant advantage with its dual expertise – as an established producer of aerostructures (handled by its industry division, with products that equip Airbus jetliners and helicopters, Boeing jetliners, Dassault and Gulfstream business jets…) and as an aeroplane manufacturer (handled by Daher’s Aircraft Division with the TBM and Kodiak airplanes, covering the full scope from design, development, certification and production, through in-service support).

“Daher is a family-owned company, which enables it to take the longer-term view for everything from research and development to the growth of its industrial resources through acquisitions – including the 2022 purchase of a large aerostructures assembly facility in the US (making Daher a Tier 1 aerostructures supplier to Boeing), and the 2019 acquisition of KVE Composites Group, which brings extensive expertise in the induction welding of thermoplastic composite components.

“Daher bases its long-term business strategy on five-year strategic plans, which set realistic goals across its activities. The latest five-year plan is called “Take Off 2027,” launched in 2023, with two of its goals being to innovate and decarbonise.”

Daher devotes a significant part of its research and development budget to thermoplastics.

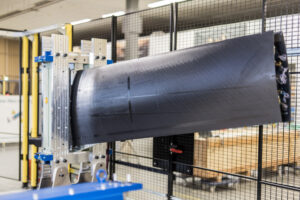

During JEC World 2024 last week, Daher and its KVE subsidiary exhibited a full-scale torsion box demonstrator for aircraft applications, which was produced using welded thermoplastic composites.

“The mechanical properties of thermoplastics make it possible to use less material and reduce the mass of aerostructures – all of which are key qualities with a view toward reducing carbon emissions,” Bailly said.

“Additionally, the material lends itself more easily to innovation in production, which includes increased automation to meet shorter production cycles and more rapid ramp-ups in output, as well as its ability to be welded. Two other important advantages of thermoplastics in the lifecycle of a product are its repairability and recyclability.

“This is why Daher is doing everything it can to accelerate the development of real applications for the benefit of its customers.”

Daher is also investing to be able to reprocess more than 80% of the production scraps with thermoplastics: they will be shredded, transformed into granules (compounding) and the obtained material will be stored and made available to produce other parts.

One of the nearer term recycling applications is Daher’s successful manufacture of rudder pedals using recycled production scraps from high-performance thermoplastic composites for installation on the TBM high-speed turboprop-powered airplanes built by Daher’s Aircraft Division.

This resulted from more than three years of research and development work, with the thermoplastic rudder pedals now certified for flight.

“Lightweight, more comfortable due to their low thermal conduction, and with equal or even better physicochemical and mechanical properties: it’s a win-win,” Bailly added. “And in addition to the environmental benefits, the cost of these parts is significantly reduced compared to metal machining.”

As part of the company’s longer-term research and development on the use of thermoplastics in aerostructures, Daher is leading the largest current French research project on thermoplastics: TRAMPOLINE 2 (TheRmoplAstic coMPosites for hOrizontaL tail plaNE).

Organised through the French CORAC (Council for Civil Aeronautical Research), TRAMPOLINE 2 represents a new step-change in technology by introducing no-rivet thermoplastic induction welding.

Making this transition will deliver weight savings of between 5% and 10%, as well as significantly reduce assembly times for sub-assemblies.

The first practical step in this direction is the production of a full-scale demonstrator of a thermoplastic torque box – assembled with the use of the exclusive induction welding process from KVE. The thermoplastic torque box is sized for the horizontal tailplane of the TBM, and was unveiled at JEC World 2024.

Separately, Daher has obtained the first results of an R&D project called CARAC TP, carried out in collaboration with a set of academic laboratories competent in composite materials.

The objective is to identify and characterise the thermoplastic composites best suited to aeronautical applications, and compare them to thermoset materials.

The project makes it possible to study materials in depth through multiple tests that go beyond the scope of qualification programs carried out in the industry: impact resistance, fire resistance, environmental aging (ozone, UV, fluids), impact of manufacturing processes on physicochemical properties and material performance.

Subscribe to the FINN weekly newsletter