Toray Advanced Composites has been working together with pioneers of the UAM and AAM market to create materials which meet the three pillars of the emerging industry’s requirements: strength, weight and safety.

The company will be showcasing materials and products which enable the affordable development and mass production of the UAM/AAM market at the Global Advanced Air Summit next week on March 2-3.

As well as enabling a whole new transport sector, Raoul Starmans, Segment General Aviation EMEA said, lightweight advanced composite materials which will feature on the next generation of eVTOLs and regional electric aircraft would contribute to their efficiency “one of the green tools in our toolbox.”

Toray works with industry pioneers, including Lilium and Joby Aviation but Starmans said the role of the company was to remain in the background, providing strength and capability through composite materials. He said: “It’s the vehicle that will enable the transportation of the future. We are behind the scenes supporting OEMs with Material Science”.

Starmans said he couldn’t give a timeline when the first AAM vehicles would be in the air, but he believed the usage of composites will grow exponentially as the sector developed.

“How long is it going to take before we see these aircraft all around us? That is basically the million dollar question. Lots of things need to go right for this to happen. And we are definitely supporting those elements”.”.

The company will also be participating in the Advanced Technology eVTOL panel discussions at GUAAS, as well as several presentations during the accelerator sessions.

FINN digital content editor Katherine Simmons talked to Raoul Starmans and Jenny Hodgson, Marketing Manager EMEA, about the company’s participation at GUAAS and how the ability to scale would ultimately define the growth of a new generation of aircraft.

Can you describe Toray Advanced Composites’ activity at GUAAS 2022?

JH: “Toray is a first time exhibitor to GUAAS but we know Farnborough as a regular exhibitor at Farnborough Airshow. We’re excited to contribute to the conference programme and share our experience and insight from the manufacturing supply chain perspective with the wider UAM network.”

What experience can Toray Composites bring from working across other sectors to UAM?

JH: “Toray is a vertically integrated global player in the aerospace and automotive industries, with production locations on three continents. We offer supply chain stability and the production capacity needed for large scale operation.”

RS: “As a trusted supplier to the aerospace industry, we offer qualified production lines and certified database materials, these include public database materials but also qualifications with OEMs and Tier 1 and 2 suppliers. Our extensive experience of certification process and testing capabilities will be of great value to support UAM players towards Type Certification.”

“Toray’s unmatched carbon fibre portfolio and production capability allow us to offer a wide variety of products suited to novel and demanding UAM aircraft design. We are at the forefront of material innovation, a good example is our Torayca T1100G IM+ fibre which offers the highest strength to modulus ratio in the market, thereby enabling further weight reduction which is crucial for electric flight.”

“Building on our automotive heritage we are able to offer cost competitive materials that are suitable for high volume production, these capabilities will be important for next generation UAM aircraft.”

“Our services extend beyond supplying the broadest range of high performance materials with trusted heritage. Our global team of technical expert services engineers support our customers in developing their applications, through material certification, engineering and processing assistance as well as providing supply chain solutions through our extensive network of business partners and technology.”

“We operate across civil aviation and general aviation to smaller aircraft like Cirrus and Icon within the business jet segments. Again, they all have varying needs in terms of the production capacity and the material technology they need to include in their structure. In terms of our experience, even within aviation that spans general aviation through to large commercial aerospace, and again, you’ve got the consideration of the supply chain for manufacturing and the material is one part of that process.”

“We say that there’s a design, material and process triangle, they’re all very much interlinked. So it’s about having that flexibility and heritage to support a programme from prototype all the way through to high volume manufacturing. That is something within aerospace that we have that breadth of knowledge to support from from end to end.”

RS: “Scale is a factor in preparation for a future where we will hopefully see a large number of these aircraft flying. You need to prepare for high volume production but the traditional aerospace industry is not high volume.”

volume.”

“We have a long history in supplying the automotive industry as well as the aerospace industry. So for aerospace, what we see in the first generation of aircraft is that the focus is really on type certification. You want to have your first flying aircraft certified so that you can really start your operations and then that’s going to be crucial for all the UAM companies because without a product, you’re still in development mode.”

“Our certifiable materials allow the company developing the aircraft to do equivalency testing on the material and basically, cut out a number of tests before you go to EASA or FAA to apply for type certification. It will condense time to market so much more than conventional database thermoset materials. We have the aerospace heritage so we can support the testing, even in our own labs, to support the customer to get to that type of certification application very quickly – that’s really important.”

“Toray is a vertically integrated company. So we have carbon fibres and we also make the resins and then make the intermediary product. We have new innovations, for example, fibres with better electric conductivity and we are able to bring all of that to the players. It’s very often needed because of the novel designs that you see in urban mobility.”

Toray is already working with UAM leaders such as Joby Aviation and Lilium. Can you describe your role in supplying pioneers of the new technology?

RS: “Joby and Lilium are the pioneers of UAM, we help them to select materials and then helping them with the forward path to type certification. We basically build up a roadmap to certification and that means equivalency testing in-house or at outside labs. Once you have the material, you need to support the customer to set up the processing facility so what we do is we have engineers on site helping calibrating machinery. We can even review designs so it’s really supporting them all along the way.”

“A big factor as well for companies like Lilium and Joby that are going to be big, is that you are able to supply going forward. You need to be able to offer capacity and supply chain sustainability. And it is important to have production at locations globally to enable companies like Joby to expand production into other continents as well.”

“Scale is definitely important but there is also a very broad area of environmental factors that will enable AAM to become successful. Regulation is very important. Joby and Lilium have been spending a lot of time to minimise the noise of the aircraft but also freeing up the airspace. There’s so many elements to the success of urban air mobility, and we are part of it.”

“We hope to support development programmes, for example, to further reduce noise of the propellers. There’s a lot of things ongoing and what we do is enable companies to bring that product to market.”

JH: “Our specialisms really do span a broad technology base, whilst benefiting from the technical intimacy of being vertically integrated as the world’s largest manufacturer of carbon fibre. We are a leading developer of specialist composite materials for high temperature applications, fire retardant and FST compliant materials for interior cabin structures, integrated lightning-strike protection, carbon-free and electrically pure materials for radomes and communications panels, as well as structural and semi structural vehicle applications. Our carbon-fibre reinforced composite materials with aerospace grade certified databases (NCAMP, CMH-17) to enable a swift path towards Type Certification. This is crucial for success as each UAM player is under pressure to realise its EIS (Entry into Service) targets.

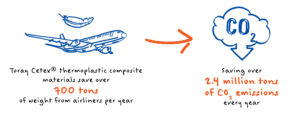

“We are also a leading developer and manufacturer of advanced thermoplastic composite materials, under our brand name Cetex®, which is in use across civil and business aviation sectors and certified to OEM qualifications. Thermoplastic composites are ideal for larger volume aerospace programmes due to their inherent lightweightness, short cycle times, and end of life recyclability, thereby offering a sustainable solution to the anticipated future build rate requirements of the eVTOL market. Cetex® is used for primary and secondary aerostructures across programmes including the Airbus A350 XWB and Gulfstream business jets.”

“We are also a leading developer and manufacturer of advanced thermoplastic composite materials, under our brand name Cetex®, which is in use across civil and business aviation sectors and certified to OEM qualifications. Thermoplastic composites are ideal for larger volume aerospace programmes due to their inherent lightweightness, short cycle times, and end of life recyclability, thereby offering a sustainable solution to the anticipated future build rate requirements of the eVTOL market. Cetex® is used for primary and secondary aerostructures across programmes including the Airbus A350 XWB and Gulfstream business jets.”

“Toray has also developed materials to enable the advancement of battery certifiability, such as Toray’s GULFENG™, a flame retardant fabric. Our technical engineers and network of technology centres are there to support our clients deploy the next generation of mobility solutions at every step of the way.”

Toray is leading a consortium to create long-life, composite liquid hydrogen tanks for civil aviation. Can you describe any other activities you are undertaking with regards to enabling cleaner fuel sources for the emerging UAM market?

RS: “We are involved in developing battery casings but within the Toray group with materials that go inside the battery, for example, carbon films that are going inside lithium ion batteries.”

“It’s also functional materials for cleaner fuel sources that we offer. For example, it could be a thermoplastic casing, where we have a fire retardant material. You might also need materials that can withstand high flames for shorter periods of time.”

JH: “As a developer of advanced lightweight materials, we are heavily invested in all elements of a more sustainable, greener future. In addition to hydrogen tanks, our company is also enabling the advancement of battery technologies, both through the inherent lightweighting benefits that our materials provide by extending the range that electronic vehicles can travel, but also through materials within the batteries themselves. Alongside emergent fuel sources, we have a longstanding heritage in creating fuel efficient structures through our lightweight structural and semi-structural composite materials, thereby ensuring that alongside greener fuel sources, the consumption of fuel is as efficient as possible.”

With the industry committing to net zero carbon emissions by 2050, can you describe how Toray Advanced Composites is meeting these ambitions across its operations?

JH: At Toray we have implemented a global “Toray Sustainability Vision” initiative across the organisation, which focuses on both external and internal actions that are needed to create a more sustainable future.

“By 2030 we are committed to reducing greenhouse gasses by 30 per cent across the entire organisation, reduce water usage in production activities by 30 per cent, as well as developing material solutions that will also inherently reduce C02 emissions in wider society.

“Our UK site holds ISO 14001 environmental management system certificate, to manage immediate and long-term environmental impacts of our operational processes and the products that are produced. We’re proud to say that our commitment extends beyond our operations.”

“As a responsible social “citizen”, we also partner and invest extensively across industry and academia to research and develop optimised uses of our material, to minimise waste both upstream and downstream in the supply chain, and develop applications for recycled carbon fibre and thermoplastic composite materials.”

“Our materials were recently recycled into an actual flying component for the V-280 Bell Helicopter – the first time that recycled thermoplastic composites have flown, ever!”

And finally… what aspects of GUAAS will you be most looking forward too?

JH: “Connecting with the international community once again! Our entire team is excited to be able to connect with the market face-to-face. There have been many developments over the last two years that want to share without the restrictions of digital ways of communicating.”

RS: “We’re also excited to see the lineup of companies at GUAAS such as Vertical Aerospace, GKN, Collins and Eve Mobility. Besides Toray telling the industry what we are all about, it also offers us the opportunity to meet up with them.”

“What you often see at the shows is that you get to learn specific questions or pain points that customers are working on. It’s so much easier to sit down with someone at a trade show, discuss things and put plans into place that you can follow up on as opposed to doing it online. It’s the human interaction that really is something that we’ve missed. I’m quite sure that once the pandemic is over, we will all happily go back into the exhibition mode. People talking to people, that’s what it’s all about.”

“There has been so much acceleration in this segment in the last two years since we’ve been in lockdown. So much has changed since 2019, since we last, really, freely connected with people on more of an international level.”

“We’re so excited to go out and share those developments with customers. You cannot always just put good things out in publications or in press releases. It will be great to speak to customers, to engineers about the developments that have been ongoing – it’s just good to get out and meet the industry again.”