When people discuss urban air mobility (UAM), there’s electricity in the air. And it needs to stay there. Concerns about batteries are among the biggest challenges involved in developing flying taxis. Companies need lightweight power storage that stays cool, safe and securely sealed, while delivering reliable performance. Now, a range of innovative and sustainable solutions is making that possible.

Batteries for eCars face high expectations – but demands for electric vertical take-off and landing (eVTOL) aircraft batteries are on another level. The power supply is the most important component in the success of eVTOL aircraft. Right now, engineers and designers are racking their brains in a search for hyper-efficient batteries that deliver more range. They also need solutions that enable rapid recharging rates or removable batteries. That’s because UAM vehicles like flying taxis are expected to take off and land frequently, with short turnaround times.

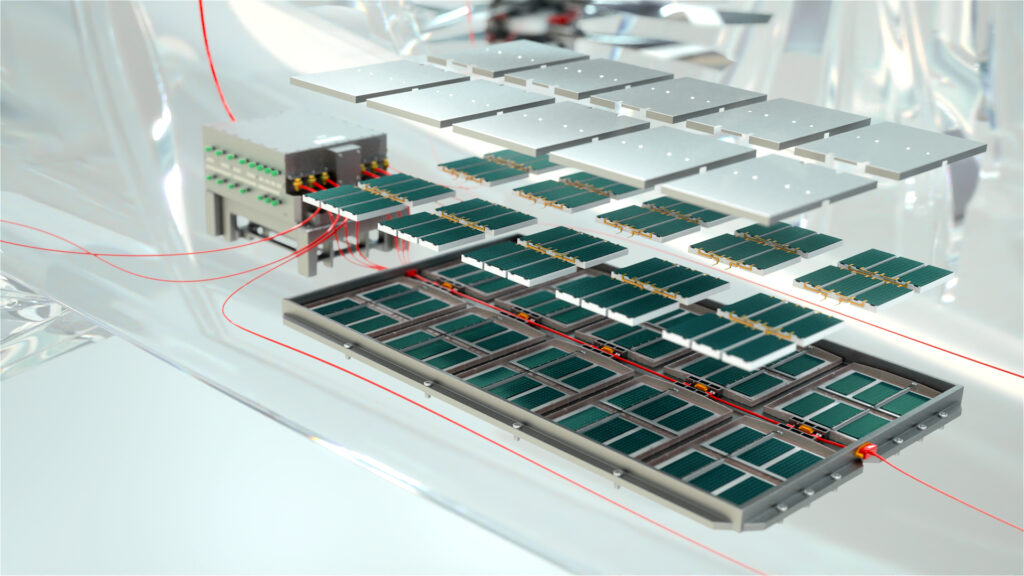

On top of these challenges for design and performance, UAM battery packs also need to offer several additional functions and features. Lightweight solutions are important for vehicles that aim to soar through the sky and play a key role in preserving energy consumption during operation. Batteries also need effective thermal management technologies because UAMs generate a lot of heat, especially during take-off and landing, making it crucial to address flame retardance for overall battery safety. Additionally, the power-supply unit requires safe and secure sealing to stop electromagnetic waves, dirt, water vapor or rain from damaging the battery.

Competitive advantage

Companies in this emerging industry are now exploring several potential eVTOL designs. This includes tilt rotor, multi-copter and fixed-wing multi-engine approaches. Each of these designs places unique requirements on the vehicle battery. It’s possible to overcome challenges related to vehicle range by using swappable batteries, which are commonly included in fixed-wing and multi-engine approaches.

However, these systems also place the highest demands on battery performance. To grab a competitive advantage in the market for affordable and emissions-free flight, companies need to achieve a successful response to additional trends related to eVTOL batteries. First, they need to optimize their production processes by considering potential opportunities for automation, additive manufacturing and other advanced technologies. They also need to integrate lightweight and miniature sensors, as well as other components that enable constant data collection and communication. Sustainability is also important. Companies need to integrate environmental and social responsibility into their material choices, while making recyclability a priority in all designs too.

The right partner

In a fresh new market with such a futuristic technology, companies may feel like they are facing unprecedented design challenges without existing solutions. That’s a lonely feeling. But a strong partner can help. Joining forces with a market-leading provider that offers cross-industry expertise from across the aviation, automotive and electronics industries can open up the path to optimized eVTOL battery function.

Henkel is that partner. The company offers a comprehensive technology portfolio for large-scale battery production, adhesive thermal management, electronics assembly and semi-conductor manufacturing. That portfolio includes conformal coatings, adhesives, non-conductive pastes, potting compounds, sealants and encapsulants, thermal pads and films, and much more.

Thermal interface materials (TIMs), for example, are a highly effective option for companies in this market. They improve thermal capabilities within high-density batteries, as well as smaller PCBs and sensors. They are proven to increase performance and lifetime, while enhancing shock resistance.

Structural adhesives are another solution with vast potential in the market for UAMs. These materials are flexible and thermally efficient and manage heat to ensure reliable battery function – while also delivering outstanding levels of bond strength and safety.

State-of-the-art technologies from the Henkel portfolio have a long track record of opening up innovative design possibilities in industries around the globe. Now, pioneering companies in the dynamic market for eVTOLs are exploring the potential to work side by side with technical experts from Henkel to enable powerful new designs that meet the challenging demands for battery safety and performance, while also supporting efficient production process and sustainability.

As a total solutions partner, Henkel is ready to share its cross-industry expertise and extensive product portfolio for battery applications. When you talk to Henkel’s team about UAMs, there’s electricity in the air. Together, we can make sure it stays there.

Visit the Henkel website to learn more.

Subscribe to the FINN weekly newsletterYou may also be interested in

How Henkel is helping to power the logistics drone revolution