Cranfield Aerospace Solutions (CAeS) has claimed a milestone with the successful integration design of its hydrogen fuel cell technology into the nacelle of an aircraft, marking “a significant step towards certification and commercialisation of the company’s zero-emissions technology.

At the core of CAeS’s mission is the development of a hydrogen fuel cell drive train that will be a safe, certifiable, and commercially viable solution for the aviation market. By packaging the entire full power system (hydrogen fuel cell system and motor) into the nacelle, CAeS has identified all the key technical and packaging challenges of designing a safe and efficient hydrogen power train and found solutions for them all.

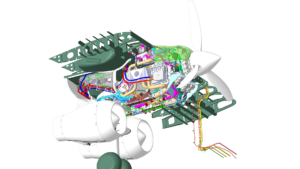

While hydrogen fuel cell technology itself is not new, adapting it for aviation poses unique challenges. The successful integration of a 240kW system (110% of the power of the engine that it replaces) into the nacelle showcases CAeS’s ability to overcome these challenges and is a “miracle of packaging” that underscores the feasibility of hydrogen-electric propulsion systems for aircraft. Moreover, this achievement positions CAeS as a leader in commercialising zero-emissions aircraft, contributing to the industry’s efforts to mitigate its environmental impact.

Behind this milestone lies a formidable engineering effort. The design team faced numerous challenges in packaging the hydrogen fuel cell along with its electrical components, cooling equipment, pipe routing, and cable routing. Space within the nacelle is extremely limited, making it particularly difficult to find an effective solution that also meets all the stringent safety requirements that we have set ourselves.

Behind this milestone lies a formidable engineering effort. The design team faced numerous challenges in packaging the hydrogen fuel cell along with its electrical components, cooling equipment, pipe routing, and cable routing. Space within the nacelle is extremely limited, making it particularly difficult to find an effective solution that also meets all the stringent safety requirements that we have set ourselves.

The forward section of the nacelle houses the Hydrogen Fuel Cell System (HFCS) itself, the HFCS Balance of Plant (BoP), an electric motor, inverters and controllers, a pitch control unit, and all the electrical cabling/routing and cooling systems for the HFCS. The rear nacelle contains the ground power interface and the high voltage power distribution system, each with its own cooling and packaging challenges.

Mounted around the existing main landing gear is the structure for the HFCS heat exchangers, which includes relevant pipework for the HFCS cooling system. This integration required meticulous planning, iterative design, and close coordination with partners Reaction Engines, to ensure optimal performance.

Subscribe to the FINN weekly newsletter